Single crystal furnaces are mainly used to manufacture high quality single crystals, and convert raw materials into single crystal materials by melting method, which is applied in semiconductor, optoelectronics, material science and other fields.

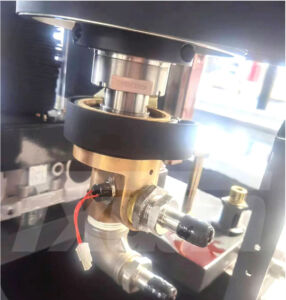

The driving component of the crucible shaft is one of the core components of the single crystal furnace. The cooling water rotary joint is installed in the lower part of the crucible shaft, which mainly plays the role of cooling and rotating sealing, and realizes the transmission of the cooling water in the fixed pipe and the hot water discharge after heat exchange.

This rotary joint has been successfully applied to a number of leading enterprises in the photovoltaic industry, according to the requirements of the field conditions, complete the selection of delivery and installation, with temperature sensors, to meet the production needs of customers.